WORLD LEADING

MANUFACTURER

Gradeall International is a world leading manufacturer of

balers, compactors, tire recycling machines and specialist bespoke recycling machinery.Now we are offering our range of tire recycling equipment across the United States

About

Gradeall International is a world leading manufacturer of recycling machinery and waste compacting solutions.

We are aiming to be the number one supplier for tire recycling equipment across America. From Texas to California, we are passionate about helping our customers dispose of their waste tires efficiently and responsibly.

Currently, US processing facilities are having to pay expensive rates for waste disposal and recycling processes.

- In 2017, Stamford, CT made $95,000 by selling recyclables, but in 2018, it had to pay $700,000 to have them removed.

- Bakersfield, CA used to earn $65 a ton from its recyclables but after 2018, it had to pay $25 a ton to get rid of them.

Paying for waste management solutions can be expensive, and disposing of tires in the US is no different.

Tire Disposal In The US

The US disposes of 269 million waste tires each year. Under US law, whole tires are not allowed to be buried in landfills. They take up too much space, become buoyant over time and release methane gas to the surface too quickly, which causes health and hazardous risks.

For landfill disposal, the solution is to cut them up. Shredded tires can be more tightly compacted into landfill space and the tire pieces are not buoyant, which means methane gasses do not surface and mosquitoes are not attracted to the stagnant water that whole tires create.

Once tires are cut up, they are considered regular garbage within the US, meaning cheaper disposal rates for businesses and possible recycling opportunities.

There are increasing efforts from businesses and US states, to avoid tires going into landfills. Vermont in particular, is actively working to find innovative uses for scrap tires.

Some recyclable uses for tires have included fuel sources, playground equipment and artificial turf.

Businesses within the US have two methods for conducting their tire disposal process.

- Hire a third party to collect whole tires, cut whole tires and dispose of them.

- Install tire recycling machinery within the workplace and treat them as part of the regular garbage disposal process, or recycling efforts.

Investing in tire disposal machinery can be very cost effective for businesses within the US, compared to hiring out a third party to conduct the disposal process. As well as costs, there are many other reasons why tire baling is an attractive option.

Gradeall can supply your business with bespoke, high quality tire disposal machinery. Get in touch today to discuss how we can help your businesses tire disposal process.

Types of Tire Recycling Machinery

At Gradeall, we specialize in high quality tire recycling machinery that will make the tire disposal system more efficient for your business.

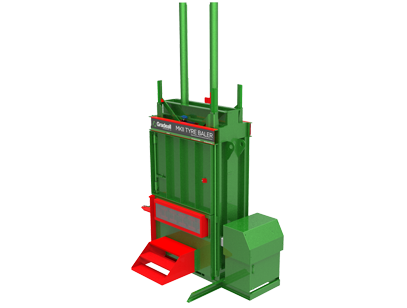

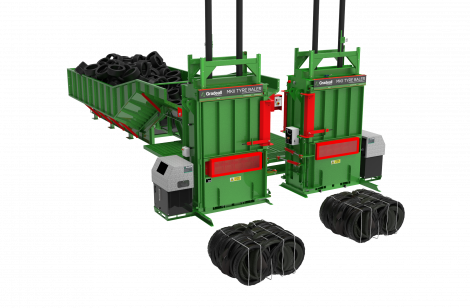

MKII TIRE BALER

Gradeall has produced the MKII Tire Baler to make recycling car tires and other lightweight tires more efficient.

It is designed for baling scrap and waste tires into uniform bales. The consistency in the size of these bales also maximizes the efficiency on truck loads and shipping container space.

Typical industries that would require a MKII Tire Baler includes waste tire collectors, waste tire transporters and waste tire recyclers.

https://www.youtube.com/watch?v=F5gSxVWj-XY

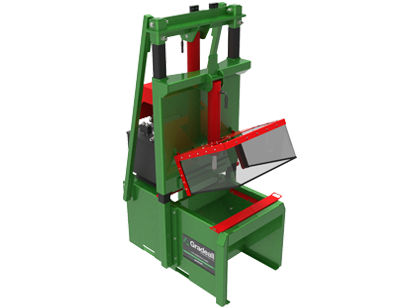

TRUCK TIRE BALER

Gradeall has produced the Truck Tire Baler to assist in disposing tires from large commercial vehicles, such as buses and trucks.

This is a cost effective piece of equipment in terms of operational costs. This machinery is operated by two people and semi-automatic, in that the loading is manual, but cycling is done automatically, with manual bale tying using wire strapping. A forklift will remove the bale with a chain ejection system.

https://www.youtube.com/watch?v=QulaUhXZHSQ

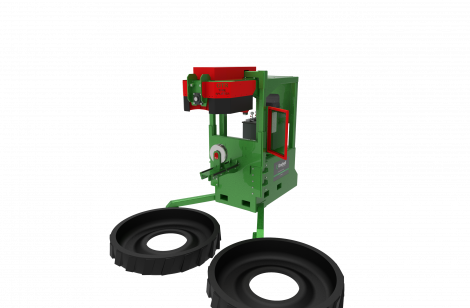

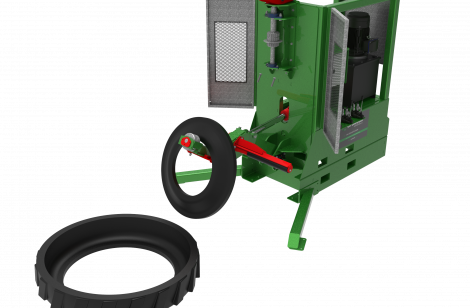

TIRE RIM SEPARATOR

Gradeall has produced the Tire Rim Separator which is ideal for separating the parts of a road wheel – removing the alloy or steel rim from the rubber tire.

The rubber is separated and ready to go through the tire disposal process. The waste steel recovered is also very profitable and offers a return on investment for this machine.

https://www.youtube.com/watch?v=HNHzXyyCWpw

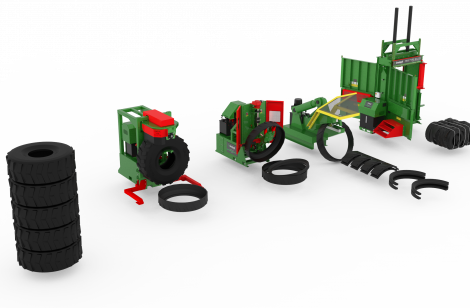

SIDEWALL CUTTER

Gradeall has designed in-house, the Sidewall Cutter. It is our bespoke, high-quality machine which provides an effective solution to sidewall cutting.

Whole tires are brought to the Sidewall Cutter machine which then picks them up, cuts the sidewalls using a tool steel grade cutting blade, and deposits the cut tire back onto the ground. After this process, you are left with two sidewalls and one tread section.

https://www.youtube.com/watch?v=sYdgdmudzsk

Gradeall International Ltd is based in Dungannon, Co. Tyrone, Ireland. We first started out as a manufacturer of coal grading equipment, servicing Northern Ireland and the UK.

Since then we have expanded into the recycling industry and we now supply bespoke waste management and recycling machinery internationally. We are keen on becoming the number one supplier for tire recycling machinery in the US.

Contact us